- Product Video

- Product Details

- Customer Case

|

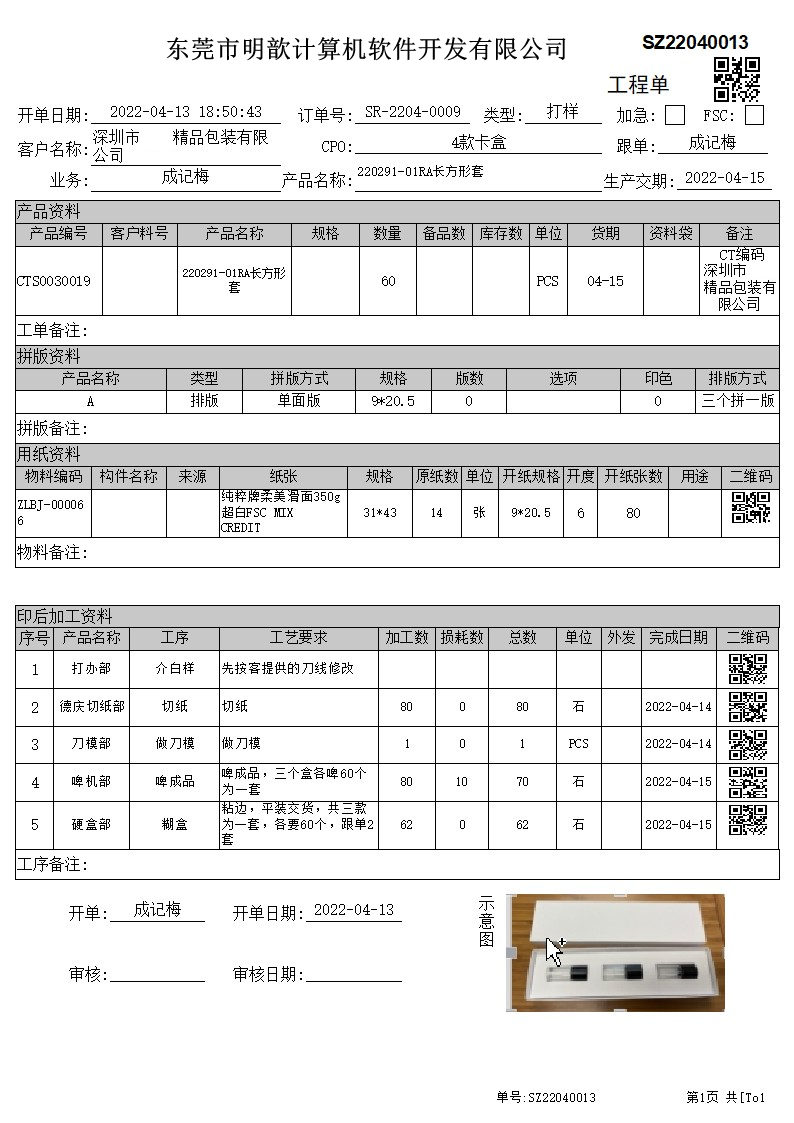

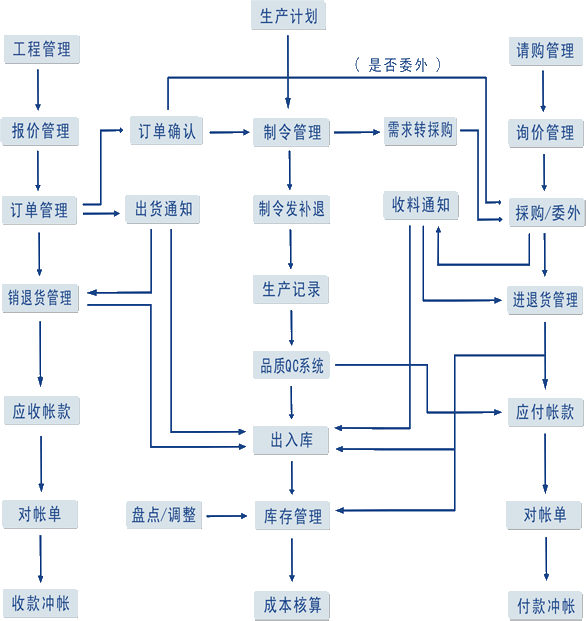

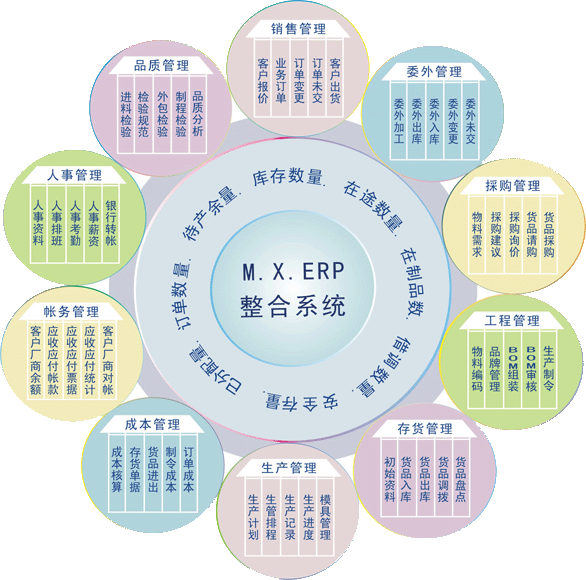

Mingxin Color Box Packaging ERP Management System is based on zero inventory, batch cost control and other management concepts. It provides complete, convenient and flexible product quotation and cost accounting functions. Its main functions include: proofing management, order management, procurement management, warehouse management, engineering management, production management, outsourcing management, sales management, financial management, Kanban, which can shorten the time for quotation accounting and improve cost and profit control, It combines production signage to track the entire process, shorten lead time, ensure delivery time, and incorporate enterprise information resources into digital management, thereby improving and optimizing enterprise production management! Version Description: Single player single player version/Multi player network version! Suitable for industries: Suitable for various packaging, color boxes, gift boxes and other printing and packaging enterprises! System functional modules: initialization information, order management, sales management, engineering management, warehouse management, material requirements, production management, procurement management, outsourcing management, cost management, personnel management, financial management, report center! Detailed introduction to system functional modules: 1. Initialization information: including product information management, department management, warehouse management, manufacturer management, customer management, and financial information Material settings, management of unit price files for goods, and so on are indispensable data for inputting documents for ERP online use Manage! 2. Order management: including valuation management, business quotation, business order, order delivery quantity query, shipment notification, and other management And assist business personnel in tracking and analyzing the progress of orders! 3. Procurement management: including inquiry, requisition, procurement, and procurement can be divided into types such as orders, work orders, and direct procurement Personnel can effectively purchase materials based on the material requirement table, enabling accurate analysis and tracking of purchased materials Purchase quantity. Effective procurement avoids the occurrence of incorrect procurement quantities or production shortages, while also facilitating procurement and production Production personnel query and follow up on materials! 4. Warehouse management: including opening, warehousing, outbound [picking], return, return to warehouse, transfer, inventory, adjustment, scrapping, and sales Inventory report management, etc., to effectively manage the entry and exit of finished products and materials, and to facilitate the management of materials This accounting comprehensively monitors and analyzes the company's materials! 5. Sales management: including the management of customer shipping orders, customer return orders, customer price history queries, etc., in order to timely Understand the shipment status and completion status of orders! 6. Engineering management: including product coding, BOM establishment, production work orders, as well as work order material budget, work order quota material requisition, etc Optimize resources and effectively control costs. Ensure timely and accurate packaging requirements for paper, ink, and accessories Accurate and quota supply! 7. Production management: including machine settings, process management, production planning, production progress query, production overrun query, and production orders Progress query, order progress query, and other functions to solve the multi loop problem of printing orders, production, and work orders from multiple perspectives Section tracking problem, completely solved the progress tracking problem of Caihe production! 8. Subcontracting management: includes functions such as outsourcing processing orders and querying the quantity of outsourced goods, which can track the production and delivery of outsourced manufacturers in a timely manner Progress status! 9. Personnel management: It includes functional management such as personnel, attendance, salary, and access control, and is a professional HR human resource management for factories Features [detailed introduction to M3 human resource management software]! 10. Financial management: including accounts receivable and payable, cost management, cash journal management, order cost accounting, and document preparation cost accounting Fund flow management with functions such as accounts receivable and payable as the foundation, ensuring effective application of funds and rapid fund utilization Return to the cage. System features: 1. A professional multi language, multi company, multi factory, and multi account set printing ERP management system that can be remotely queried! 2. After years of practice and improvement, the system has a clear process and is easy to use! 3. Improve the system log function, with a detailed event list recording the actual operation process of each user, which is conducive to checking the user's operation status! 4. All module functions and reports can be customized or saved as a separate format! 5. Permission: Only those who create the information can see it, and the supervisor can see all the information! 6. Support multi unit conversion and image management functions! 7. Support barcode scanning management for inbound and outbound inventory! 8. Complete material coding setting rules. Thus reducing the workload of repeated input by users! 9. Support mobile app scanning homework!

|

|

|

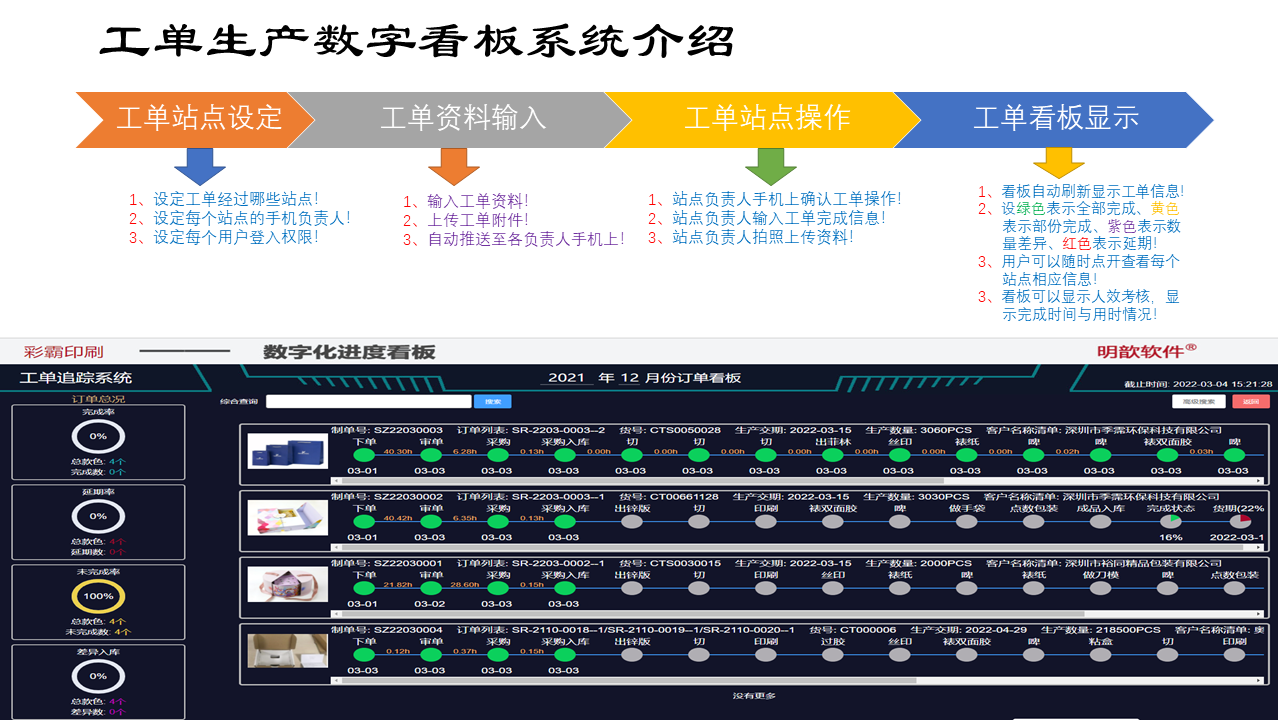

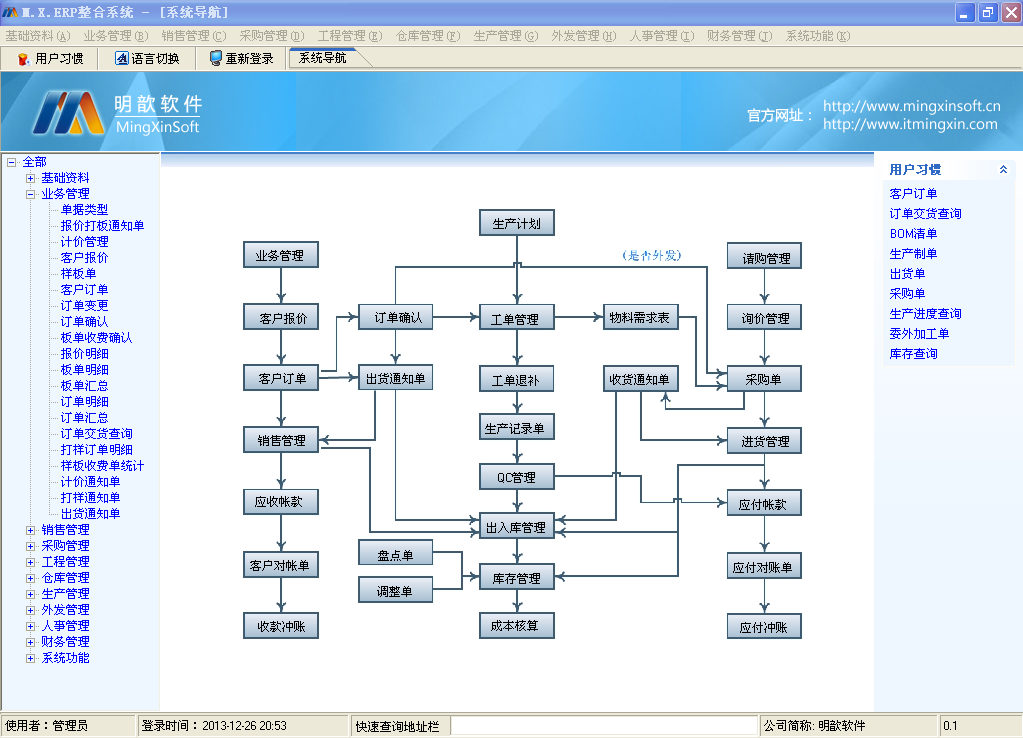

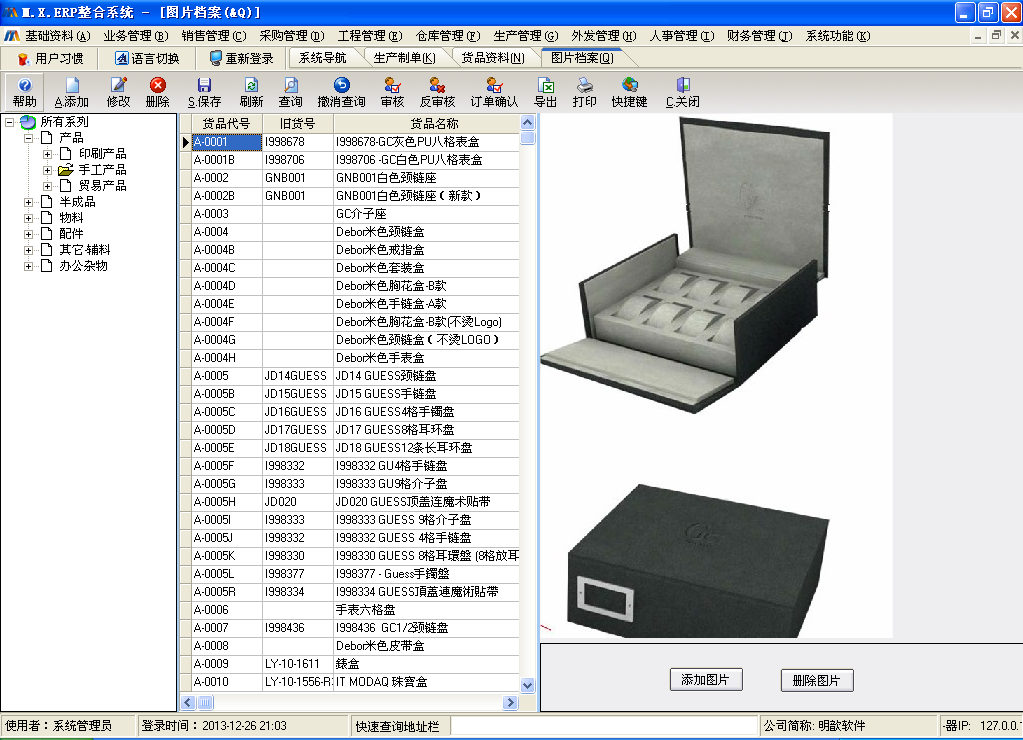

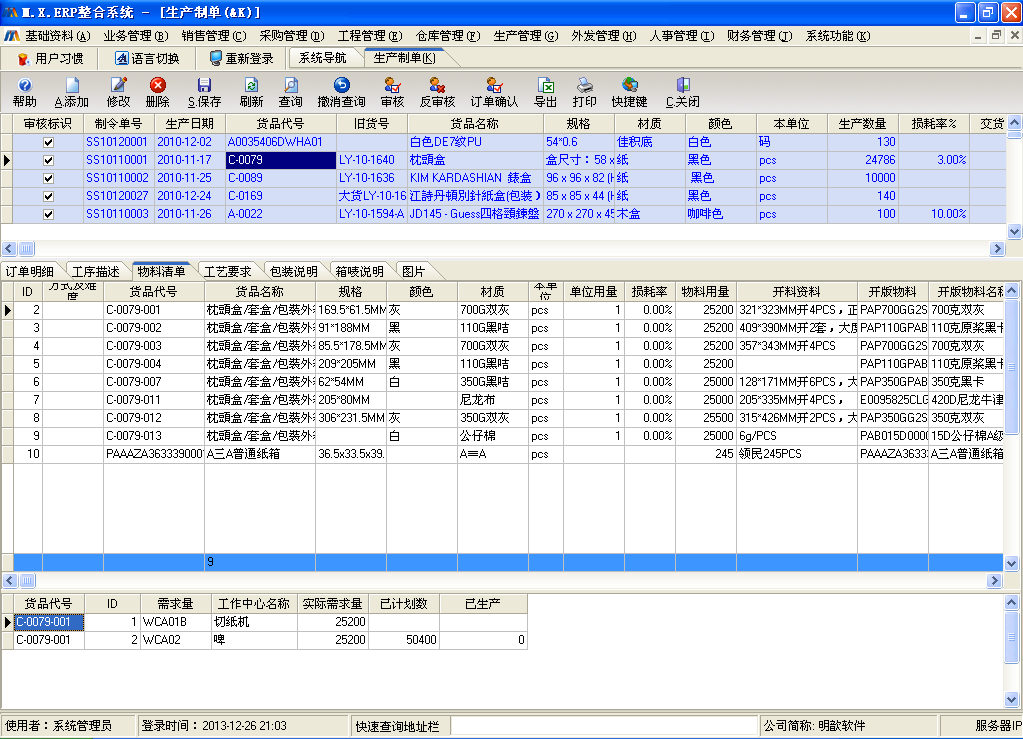

Home screen of some systems:

|